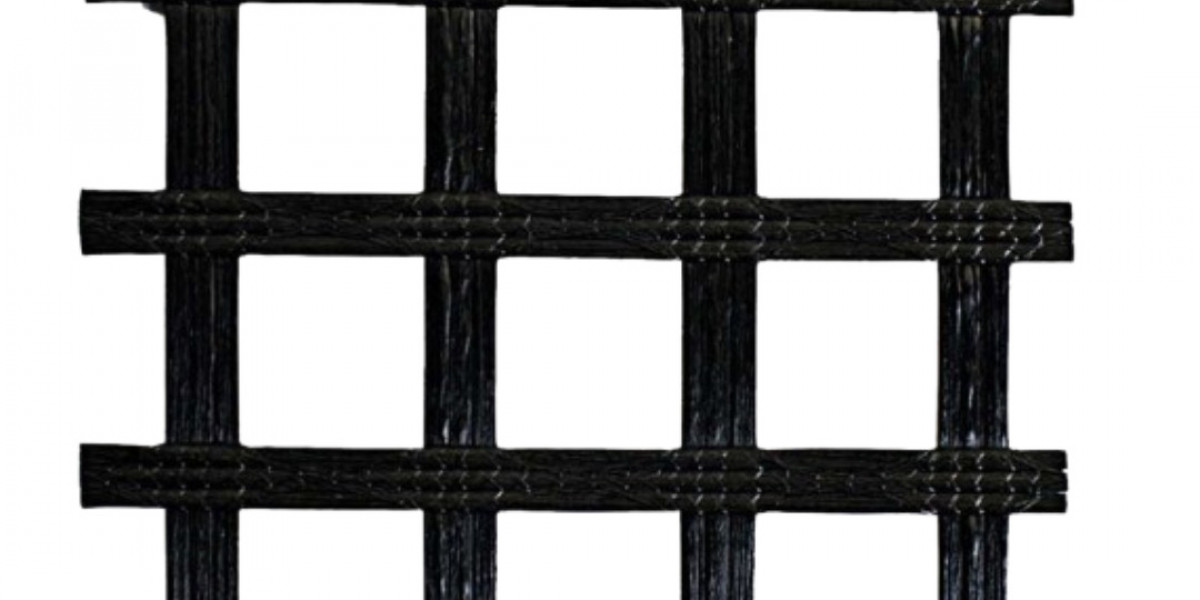

This engineered material, meticulously crafted from polymers like high-density polyethylene (HDPE), plays a pivotal role in reinforcing soil structures, ensuring long-term stability and preventing catastrophic failures. Its strength lies in its unidirectional tensile capacity, designed to resist forces in a single, predetermined direction. This characteristic makes it exceptionally effective in applications where tensile reinforcement is paramount, such as steep slopes, retaining walls, and embankments.

The inherent properties of Uniaxial geogrid exporters in Ahmedabadincluding high tensile strength, low creep characteristics, and excellent chemical resistance, contribute to their reliability in diverse environmental conditions. Unlike traditional reinforcement methods, which rely on the sheer mass of materials, geogrids interlock with soil particles, creating a composite structure that distributes loads more effectively. This interlocking mechanism significantly enhances the soil's shear strength, reducing the risk of slippage and deformation.

Applications and Benefits

One of the most critical applications of uniaxial geogrids is in slope stabilization. Steep slopes, whether natural or man-made, are susceptible to erosion and instability, especially in areas with high rainfall or seismic activity. By incorporating geogrids into the slope's construction, engineers can significantly improve its stability, preventing landslides and ensuring the safety of surrounding infrastructure. Similarly, in the construction of retaining walls, geogrids provide the necessary reinforcement to withstand the lateral earth pressures, allowing for the construction of taller and steeper walls.

Embankments, essential components of transportation infrastructure, also benefit from the use of uniaxial geogrids. These geogrids reinforce the embankment's structure, preventing settlement and ensuring its long-term stability. The use of uniaxial geogrids also allows for the construction of steeper embankments, reducing the land required for construction and minimizing environmental impact. In addition to these applications, uniaxial geogrids are used in the construction of reinforced soil slopes, mechanically stabilized earth (MSE) walls, and foundation reinforcement.

The advantages of using uniaxial geogrids extend beyond structural stability. They offer a cost-effective solution compared to traditional reinforcement methods, reducing the need for extensive excavation and material transport. Their ease of installation also contributes to faster construction times, minimizing project delays. Furthermore, the durability and long service life of geogrids ensure that the reinforced structures remain stable and reliable for decades.

Manufacturing and Export

The production of high-quality uniaxial geogrids requires specialized manufacturing processes and stringent quality control measures. In India, particularly in industrial hubs like Ahmedabad, several manufacturers specialize in the production of these engineered materials. These manufacturers employ advanced technologies and adhere to international standards to ensure the consistency and reliability of their products. The growing demand for reliable earthwork solutions has led to an increase in the number of Uniaxial geogrid manufacturers in Ahmedabadcontributing to the city's reputation as a key supplier of these materials.

Beyond domestic supply, Indian manufacturers are also actively involved in exporting uniaxial geogrids to various countries. The strategic location of India, coupled with its competitive manufacturing costs and high-quality products, makes it a preferred source for international buyers. The presence of numerous Uniaxial geogrid exporters in Ahmedabad and Uniaxial geogrid exporters in India facilitates the smooth flow of these materials to global markets, supporting infrastructure development projects worldwide. These exporters ensure timely delivery and provide technical support to their international clients, fostering long-term partnerships.

The quality of exported products is a crucial factor in building trust and maintaining a strong reputation in the global market. Indian exporters prioritize quality assurance, conducting rigorous testing and inspections to ensure that their geogrids meet the required specifications. By adhering to international standards and providing reliable products, they contribute to the growth of India's export sector and support infrastructure development worldwide.

Material and Testing

The materials used in the manufacture of uniaxial geogrids are carefully selected to ensure optimal performance. HDPE, known for its high tensile strength and durability, is a common choice. The manufacturing process involves extruding the polymer into a grid-like structure, with the ribs oriented in the direction of the primary tensile force. This orientation maximizes the geogrid's ability to resist tensile loads, providing the necessary reinforcement for soil structures.

Rigorous testing is essential to ensure the quality and reliability of uniaxial geogrids. These tests include tensile strength testing, creep testing, and chemical resistance testing. Tensile strength testing measures the geogrid's ability to withstand tensile loads, while creep testing evaluates its long-term deformation under sustained loads. Chemical resistance testing assesses its ability to withstand exposure to various environmental conditions. By conducting these tests, manufacturers can ensure that their products meet the required specifications and perform reliably in diverse applications.

Conclusion

Uniaxial geogrids have revolutionized earthwork construction by providing a reliable and cost-effective solution for slope stabilization and soil reinforcement. Their unique properties, including high tensile strength, low creep characteristics, and excellent chemical resistance, make them indispensable in various infrastructure projects. The contributions of manufacturers and exporters, particularly those based in Ahmedabad and across India, have played a significant role in making these materials accessible to global markets. The commitment to quality and reliability ensures that Uniaxial geogrid exporters in Indiacontinue to enhance the stability and longevity of earthwork structures worldwide.

Frequently Asked Questions (F&Q)

1. How does a uniaxial geogrid differ from a biaxial geogrid?

Answer: A uniaxial geogrid is designed to resist tensile forces in one direction, making it ideal for applications requiring reinforcement in a single axis, such as slope stabilization and retaining walls. A biaxial geogrid, on the other hand, resists tensile forces in two perpendicular directions, making it suitable for applications like base reinforcement in roadways and pavements, where load distribution in multiple directions is crucial.

2. Can uniaxial geogrids be used in all soil types?

Answer: While uniaxial geogrids are effective in a wide range of soil types, their performance can vary depending on the soil's characteristics. Generally, they perform well in granular soils like sand and gravel, as they interlock effectively with these materials. However, in cohesive soils like clay, proper drainage and compaction are essential to ensure optimal performance. A site-specific geotechnical investigation is recommended to determine the suitability of geogrids for a particular soil type.

3. What is the typical lifespan of a uniaxial geogrid in soil?

Answer: The lifespan of a uniaxial geogrid depends on various factors, including the material's quality, environmental conditions, and installation practices. High-quality HDPE geogrids are designed to withstand long-term exposure to soil and environmental factors, with a typical lifespan of 50 to 100 years or more. Proper installation and protection from UV radiation during storage and installation are essential to maximize their lifespan.