The global wind energy sector continues to expand as industries and governments invest in cleaner power solutions. At the heart of every reliable wind turbine lies a set of precision engineered components that must withstand extreme loads and long service lives. Selecting the right supplier for these critical parts is not a decision to take lightly. A dependable partner for Forging Windpower Generator Part production ensures operational stability, safety, and long term value. This introduction highlights why careful supplier selection is essential before exploring the key factors that define trust and quality in this specialized field.

Understanding the Importance of Forged Components in Wind Power

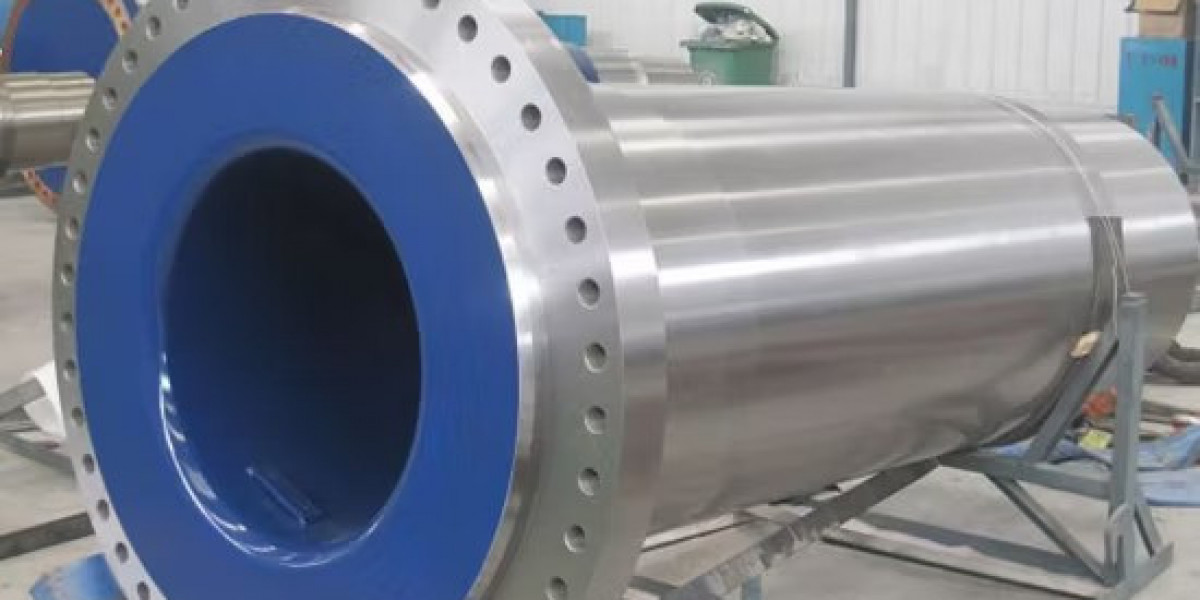

Forged components play a vital role in windpower generators because they offer superior mechanical strength, structural integrity, and fatigue resistance compared to cast or machined alternatives. Wind turbines operate under constant stress from wind loads, rotational forces, and changing environmental conditions. Forging aligns the metal grain structure, enhancing durability and reducing the risk of unexpected failure. A trusted supplier understands these demands and designs components that meet the exact performance requirements of modern wind turbines.

Evaluating Technical Expertise and Manufacturing Capability

One of the most important aspects of choosing a supplier is assessing their technical expertise. An experienced manufacturer invests in advanced forging equipment, heat treatment facilities, and precision machining capabilities. These resources allow consistent production of complex shapes and tight tolerances. A reliable supplier also employs skilled engineers who understand material behavior, tooling design, and process optimization. This level of competence directly impacts the performance and lifespan of every Forging Windpower Generator Part delivered.

Material Quality and Compliance with Industry Standards

Material selection is critical in windpower generator components, as poor quality steel or improper alloy composition can compromise safety and efficiency. A trusted supplier sources certified raw materials and follows strict quality control procedures throughout the production cycle. Compliance with international standards and certifications demonstrates a commitment to consistency and reliability. These standards ensure that each component performs as expected under demanding operational conditions and aligns with global wind energy requirements.

Quality Assurance and Testing Processes

Beyond material selection, robust quality assurance systems distinguish a dependable supplier from an average one. Comprehensive inspection methods such as ultrasonic testing, dimensional checks, and mechanical property verification help detect defects before components reach the field. Transparent documentation and traceability further enhance confidence in the supplier relationship. Consistent testing ensures that each Forging Windpower Generator Part meets design specifications and contributes to the overall reliability of the turbine.

Supply Chain Reliability and On Time Delivery

Wind energy projects often operate on strict timelines, making dependable delivery a crucial factor. A trusted forging supplier maintains efficient production planning, inventory management, and logistics coordination. This reliability minimizes downtime and supports smooth project execution. Long term partnerships are built on the assurance that components will arrive on schedule without compromising quality, even as demand fluctuates.

Building a Long Term Partnership for Sustainable Growth

Choosing the right forging supplier is not only about meeting immediate needs but also about supporting future growth. A supplier that values collaboration, continuous improvement, and innovation can adapt to evolving turbine designs and higher performance expectations. By selecting a trusted partner, wind energy developers and manufacturers secure consistent quality, technical support, and long term cost efficiency. This strategic choice ultimately strengthens the reliability and sustainability of windpower generation systems worldwide.