Introduction

The construction industry is undergoing rapid transformation thanks to innovative light construction equipment. Machines designed for cutting, bending, finishing, and leveling concrete and steel are reducing labor requirements while enhancing precision. From building foundations to finishing floors, advanced machines now deliver accuracy and productivity that manual work cannot match. Let’s explore the most reliable machines that are streamlining processes and ensuring project quality in today’s construction environment.

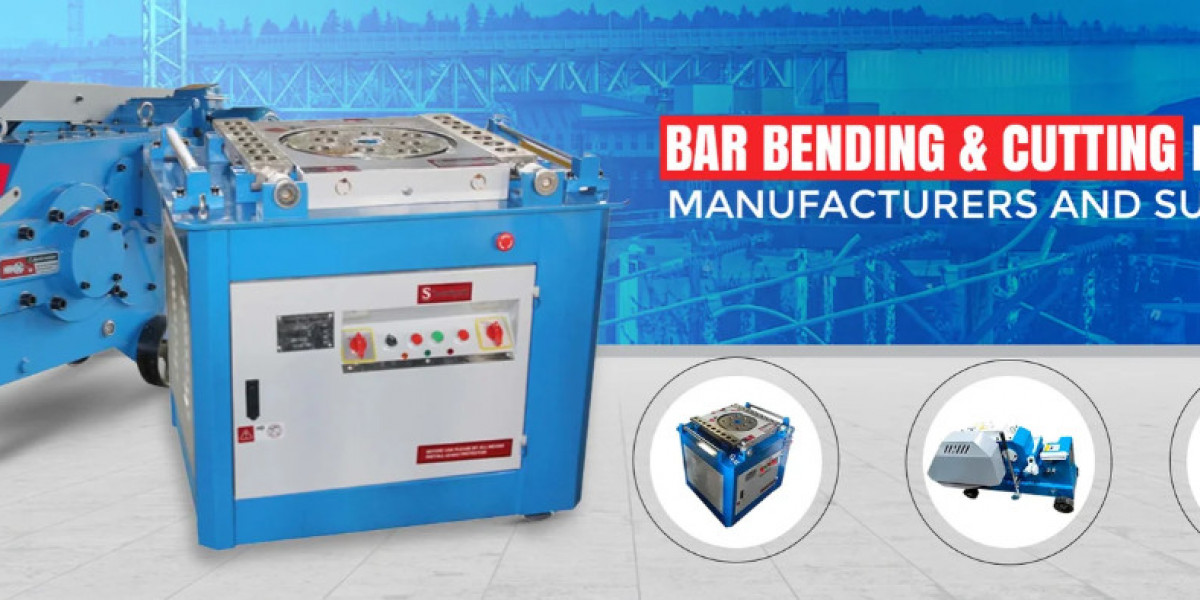

Bar Bending Machine: Precision for Steel Reinforcement

One of the most critical steps in any construction project is the preparation of reinforcement bars. A Bar Bending Machine automates the process of bending steel rebars into exact shapes required by structural designs. Its hydraulic and mechanical precision ensures uniformity and reduces material waste. Contractors depend on this equipment for bridges, high-rises, and infrastructure projects where safety and durability are key.

Bar Cutting Machine: Accuracy and Speed Combined

Steel cutting is equally important in reinforcement preparation. A Bar Cutting Machine provides efficient, fast, and accurate rebar cutting, eliminating inconsistencies caused by manual tools. The machine is designed with robust blades capable of handling continuous heavy-duty cutting tasks. Its role in project efficiency is undeniable, particularly in large-scale construction where time management and resource control are crucial for timely project delivery.

Bar Threading Machine: Simplifying Joint Connections

As construction grows more sophisticated, threaded joints are increasingly used for bar splicing. The Bar Threading Machine simplifies this by producing precise external threads on reinforcement bars. These threaded ends make coupler-based connections possible, eliminating overlaps and saving steel. With threading technology, the reinforcement process not only becomes faster but also more cost-effective, while ensuring structural strength remains uncompromised.

Multi Cutter Machine: Versatile and Efficient Tool

Beyond steel reinforcement, contractors also need equipment to cut a variety of construction materials. The Multi Cutter Machine is designed for this very purpose. Its multi-functional cutting capability makes it suitable for pipes, steel sections, and other building materials. With high cutting efficiency, portability, and accuracy, it has become a versatile tool for project sites of all sizes. This ensures productivity is never compromised when working with different materials.

Power Trowel: Finishing Concrete with Perfection

When it comes to flooring, concrete finishing can define the strength and durability of a structure. The Power Trowel ensures a polished, dense, and wear-resistant surface. Available in walk-behind and ride-on models, it is used in industrial floors, warehouses, and commercial spaces. Compared to manual finishing, the power trowel not only saves time but also guarantees smoother, long-lasting concrete finishes that enhance the overall quality of flooring projects.

Laser Level Machine: Accuracy in Concrete Leveling

Accuracy is everything in modern construction. The Laser Level Machine has redefined concrete floor leveling by combining laser guidance with automated screeding. It delivers millimeter-perfect flatness across large flooring projects. This technology reduces human error, enhances efficiency, and produces perfectly leveled floors for warehouses, factories, and large-scale commercial spaces. With its speed and accuracy, the laser level machine is transforming flooring standards worldwide.

Why These Machines Are Essential

Each of these machines addresses a critical area of construction: bending, cutting, threading, material preparation, finishing, and leveling. Together, they create a streamlined process that ensures safety, efficiency, and high-quality outcomes. By replacing manual methods with mechanical precision, contractors reduce labor intensity, lower costs, and deliver projects faster—making them indispensable in today’s competitive construction landscape.

Conclusion

The adoption of modern construction machinery has become a necessity, not a choice. By integrating bending, cutting, threading, multi-cutting, finishing, and laser leveling machines into projects, contractors ensure precision and efficiency. These machines provide not only time savings but also improved durability and quality in construction results. As infrastructure demands continue to grow, embracing such technologies is the key to successful and sustainable project delivery.