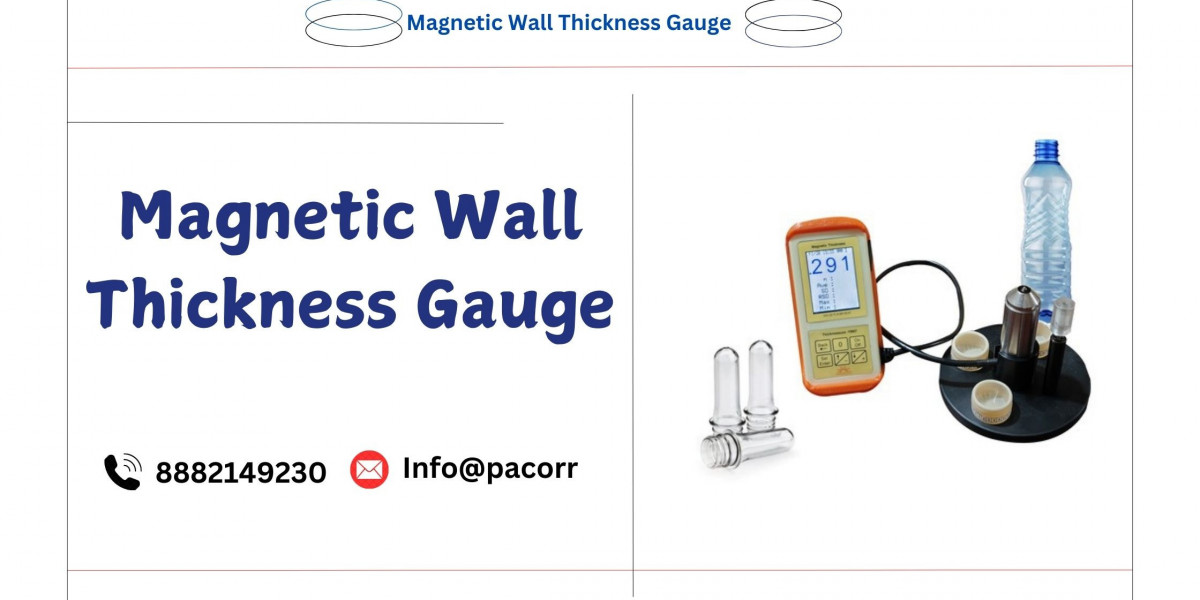

Introduction: Transforming Quality Testing with Magnetic Wall Thickness Gauge

When precision matters, the Magnetic Wall Thickness Gauge emerges as an indispensable tool for non-destructive thickness measurement. At Pacorr.com, we are committed to providing cutting-edge solutions that simplify quality control, improve efficiency, and maintain product durability.

This blog will guide you through everything about magnetic wall thickness gauges—their working principles, features, applications, benefits, and how Pacorr’s advanced offerings can meet your industry’s needs.

What is a Magnetic Wall Thickness Gauge?

A Magnetic Wall Thickness Gauge is a device used to measure the thickness of non-magnetic materials like plastics, glass, ceramics, and coated metals without causing any damage. By employing magnetic principles, it ensures high-precision results, making it a reliable tool for various industries.

How Does a Magnetic Wall Thickness Gauge Work?

- Magnetic Field Interaction: The device works by placing a magnet on one side of the material and a probe on the other.

- Thickness Measurement: The distance between the magnet and the probe is calculated, which corresponds to the material's thickness.

- Digital Output: The thickness is displayed digitally, providing quick and accurate results.

Key Features of Magnetic Wall Thickness Gauges

- Non-Destructive Testing: Measures thickness without altering or damaging the material.

- High Accuracy: Precision readings with an accuracy of up to 0.001 mm.

- Wide Material Compatibility: Ideal for non-magnetic materials such as plastics, ceramics, glass, and coated metals.

- Lightweight and Portable: Perfect for on-site and field testing.

- Easy-to-Use Digital Interface: Clear and simple displays for effortless operation.

Applications of Magnetic Wall Thickness Gauges

1. Automotive Industry

- Measuring glass, paint, and coated parts for uniformity and durability.

- Ensuring precision in component manufacturing.

2. Aerospace Industry

- Verifying thickness in lightweight materials for aircraft.

- Complying with stringent safety and quality standards.

3. Plastic Manufacturing

- Checking the thickness of pipes, bottles, and molded products.

- Reducing material waste with accurate measurements.

4. Packaging Industry

- Inspecting blister packs, vials, and food-grade containers for consistency.

- Maintaining product safety and compliance.

5. Metal Coatings

- Evaluating the thickness of protective coatings like anodizing or galvanizing.

- Ensuring longevity and corrosion resistance.

Benefits of Using Magnetic Wall Thickness Gauges

- Accuracy and Reliability: Delivers consistent and precise results for better quality control.

- Non-Destructive: Retains the material’s integrity during testing.

- Time-Saving: Provides instant, on-the-spot measurements.

- Cost-Effective: Reduces material waste and minimizes testing costs.

- Versatile Applications: Suitable for use across various industries.

Why Choose Pacorr’s Magnetic Wall Thickness Gauges?

At Pacorr.com, we offer top-quality magnetic wall thickness gauge price that stand out for their innovation, performance, and reliability. Here’s why you should choose Pacorr:

- Advanced Technology: Leveraging the latest innovations for unmatched precision.

- Robust Design: Built to withstand demanding industrial environments.

- Custom Solutions: Tailored to meet specific industry needs.

- Expert Support: Comprehensive assistance from product selection to after-sales service.

Choosing the Right Magnetic Wall Thickness Gauge

Selecting the ideal magnetic wall thickness gauge depends on your requirements. Consider these factors:

- Material Compatibility: Ensure the device works with your material type.

- Measurement Range: Verify that the range meets your application needs.

- Accuracy: Opt for models that deliver high precision for your industry standards.

- Portability: Choose lightweight designs for on-site testing.

- Trusted Provider: Rely on reputable brands like Pacorr for reliability.

Best Practices for Using Magnetic Wall Thickness Gauges

- Calibrate Regularly: Maintain accuracy by calibrating the device before use.

- Clean the Surface: Remove any dirt or debris to avoid interference.

- Follow Manufacturer Instructions: Use the device as directed for optimal performance.

- Store Properly: Protect the gauge from moisture and dust when not in use.

Emerging Trends in Magnetic Wall Thickness Gauges

The future of magnetic wall thickness gauges is geared toward:

- AI Integration: Enhancing measurement precision through intelligent algorithms.

- Wireless Connectivity: Enabling real-time data sharing and remote monitoring.

- Compact, User-Friendly Designs: Increasing portability and usability for field applications.

Conclusion

The Magnetic Wall Thickness Tester is an essential tool for industries prioritizing precision, quality, and efficiency. Whether you're in automotive, aerospace, or packaging, this device offers unparalleled accuracy and reliability.